Thermwood and General Atomics Partner on Additive Tool with Significant Cost Savings

Thermwood recently collaborated with General Atomics to produce a CNC trim tool with a significant cost savings of around $50,000 when compared to traditional methods.

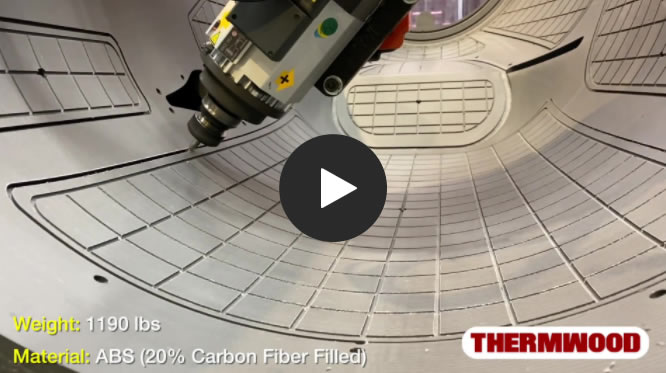

Click below to watch a video of the process:

The Details

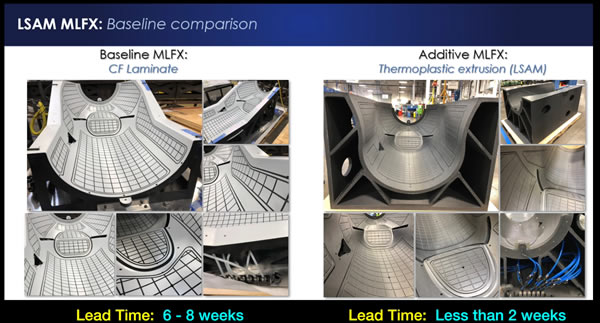

Using a Thermwood LSAM 10''x20'', the tool was printed from ABS (20% Carbon Fiber Filled) in 16 hours. Total machining time was 32 hours. The final part weighed 1,190 lbs, and represented a cost savings of around $50,000 when compared to traditional methods. Total lead time for the part decreased from 6-8 weeks to less than 2 weeks by utilizing the powerful LSAM system.

The Results

This cost and time savings breaks down to:

Cost reduction: 2-3x

Faster development: 3-4x

Final Product: A production capable tool

Vacuum Integrity: Vacuum integrity without the need for coatings

Final Result: A tool that is suitable for large, deep 3D geometries, backup structures and vacuum piping

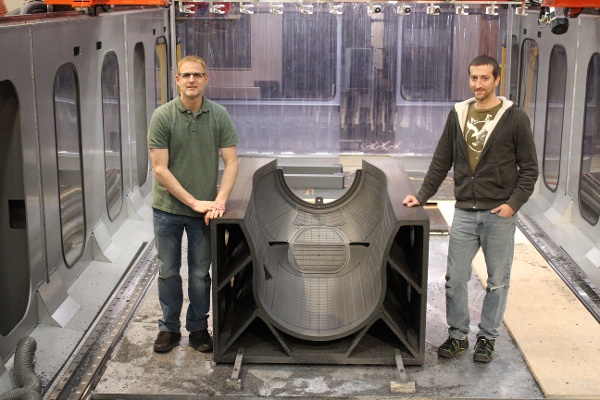

The final completed part

The final completed part

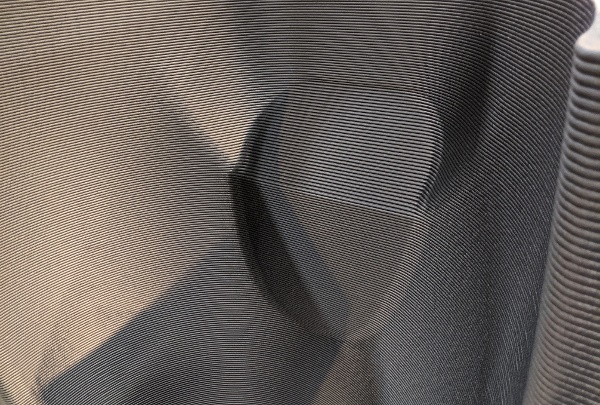

Close up of the printed part before machining.

About Thermwood Corporation

Thermwood is a US based, multinational, diversified CNC machinery manufacturer that markets its products and services through offices in 11 countries. Thermwood is the oldest manufacturer of highly flexible 3 & 5 axis high-speed machining centers known as CNC routers.

Thermwood has also become the technology and market leader in large scale additive manufacturing systems for thermoplastic composite molds, tooling, patterns and parts with its line of LSAM (Large Scale Additive Manufacturing) machines that both 3D print and trim on the same machine. These are some of the largest and most capable additive manufacturing systems ever produced and are marketed to major companies in the aerospace, marine, automotive and foundry industries as well as military, government and defense contractors.

![]()

Arts and Entertainment

Arts and Entertainment Business and Industry

Business and Industry Computer and Electronics

Computer and Electronics Games

Games Health

Health Internet and Telecom

Internet and Telecom Shopping

Shopping Sports

Sports Travel

Travel More

More