Below is a sample of the emails you can expect to receive when signed up to Ganssle.

|

||||

|

You may redistribute this newsletter for non-commercial purposes. For commercial use contact info@ganssle.com. To subscribe or unsubscribe go here or drop Jack an email. |

||||

| Contents | ||||

|

||||

| Editor's Notes | ||||

|

Over 400 companies and more than 7000 engineers have benefited from my Better Firmware Faster seminar held on-site, at their companies. Want to crank up your productivity and decrease shipped bugs? Spend a day with me learning how to debug your development processes. Attendees have blogged about the seminar, for example, here, here and here. I'll present the Better Firmware Faster seminar in Melbourne and Perth, Australia February 20 and 26th. All are invited. More info here. As I noted in a recent blog, I'm cutting back significantly on travel, so this will be my last trip to Australia. Arm has released a free e-book of interest to people integrating Cortex-M parts into their SoCs: System-on-Chip Design with Arm Cortex-M Processors. Be careful what you read. Renesas's new S1JA SoC is based on the Cortex-M23 and appears to be a heck of a part, with just about every peripheral you can imagine. But a writeup on embedded.com reads, in part: "The microcontrollers' ultra-low power extends battery life for battery-operated portable and battery backup applications. The software standby mode consumes only 500 nA to enable 20-year battery-operated applications that spend extended periods in sleep mode." Unless the "battery" is a radioisotope generator the 20-year claim exceeds the shelf-life of the batteries used in portable electronics. Getting years of life from a battery is a hard problem with many subtle issues. For more info see this (though that paper focuses on the CR2032 cell, the concepts scale to most battery types). |

||||

| Quotes and Thoughts | ||||

|

"It is better to define your system up front to minimize errors, rather than producing a bunch of code that then has to be corrected with patches on patches" Margaret Hamilton of Apollo Guidance Computer fame. |

||||

| Tools and Tips | ||||

|

Please submit clever ideas or thoughts about tools, techniques and resources you love or hate. Here are the tool reviews submitted in the past. Thor wrote:

|

||||

| Freebies and Discounts | ||||

|

This month's giveaway is a copy of Embedded Systems World-Class Designs.

Enter via this link. |

||||

| The Rust Programming Language | ||||

|

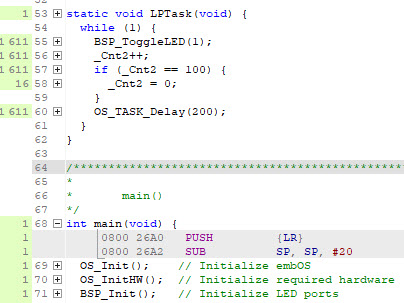

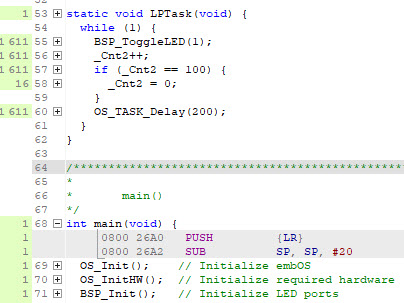

I'm getting a lot of email about the Rust language, in particular, in using Rust on embedded projects. There's a lot to like about the language. It superficially looks like C/C++. At compile time a borrow-checker tests for memory safety. Basically, each value has an owner. There's only one owner of a variable at a time, and when the owner goes out of scope, the value is dropped. Many people scream at the borrow-checker as it can cause headaches, but users report after a while they learn to abide by Rust's rules, and get a lot of benefit from the memory-safety checks, as it eliminates data races and other common problems. Here's an example factorial program, from the Wikipedia entry: fn factorial(i: u64) -> u64

{

let mut acc = 1;

for num in 2..=i

{

acc *= num;

}

acc

}

Where's the return argument? In Rust, if there's no return statement the last expression is the return value. I find that strangely appealing. The "let" keyword reminds me of the bad old days of Dartmouth BASIC. Rust is used in embedded development, and the main site has a sub-page about this, with examples using a Cortex M processor. While C is a great language for low-level programming and embedded development, it lacks modern features like strong typing (and so much more) that helps create correct programs. The SPARK people call this "correctness by construction." Ada, SPARK, and to a lesser extent Rust enforce rules which lead to safer code. Studies (e.g., Software Static Code Analysis Lessons Learned, Andy German, QinetiQ Ltd., Nov 2003 Crosstalk) show programs in Ada and SPARK have only a fraction of the defects found using C. To my knowledge there's no such data about Rust, but it seems reasonable that Rust code will be less error-prone than C code. I have seen no data on Rust's efficiency (in size and speed), bus suspect it's similar to C. However, as fascinating as it is to learn new languages, there's one place where Rust fails. It's evolving at a rapid pace, and there is no ANSI standard. That's generally not much of a problem in web development or for small embedded projects. But many embedded systems have lives of years and decades. In the railroad industry support has to be guaranteed for 30 years. What will Rust look like a decade or two hence? Will you be able to get a compiler that handles the old dialect? If you have hundreds of thousands of lines of Rust legacy code, reuse might be impossible if all of that is coded using a long-obsolete version. C made its way into the embedded space in the 1980s. Lots of compilers abounded. None were compatible. Remember Manx C? That decade was a veritable Babel of incompatible Cs which was resolved only with the advent of standardization under ANSI C 89/90. As technologists we want the best possible solution. Yet sometimes that has to take second place to business realities. Every engineering effort involves some amount of risk, but we do want to minimize that risk, especially if it could have devastating long-term consequences. Megabucks invested in developing code that can no longer be compiled is a risk that is not, in my opinion, worth taking. I look forward to the day when Rust joins the stable of standardized languages, and have no doubt we'll see that happen in the next decade or so. Standardization efforts move slowly. ANSI spent six years working on the first C standard. |

||||

| Encoder Bouncing | ||||

|

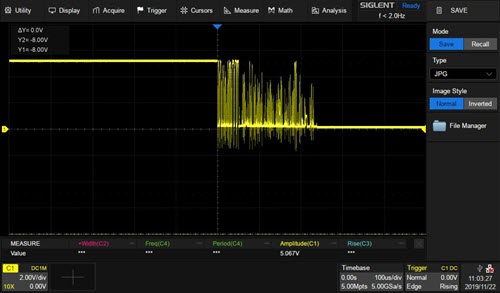

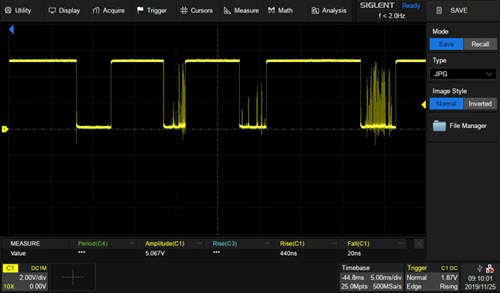

Recent Muses (TEM 384 and TEM 385) had discussions about encoders, which engendered quite a bit of interesting email correspondence. I decided to look at bounce characteristics of a few models. I picked low-cost devices as these are common in controls (e.g., radio volume controls). My focus was (mostly) on mechanical encoders, as it's reasonable to assume these will have significant bounce issues. Bourns's PEC11R-4215F mechanical encoder gives 24 PPR (pulses per revolution). The datasheet specs 2 ms bounce though that is footnoted "Devices are tested using standard noise reduction filters." It's not clear to me if the 2 ms was with or without the filter, but the unit behaved much better than specified. With no filter, this is the worst bouncing I saw:

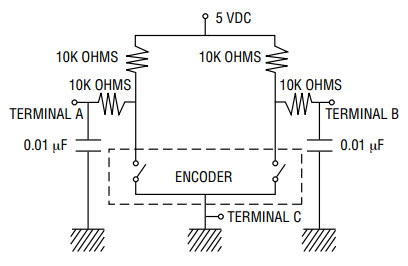

That's pretty ugly, but the bouncing lasted only about 250 µs. The datasheet recommends this circuit to clean up the noise:

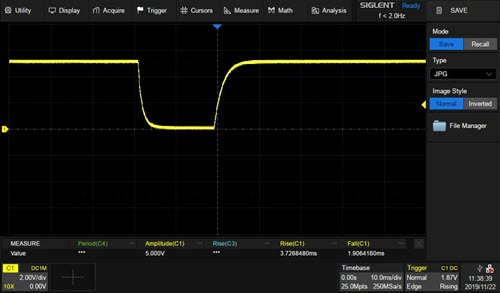

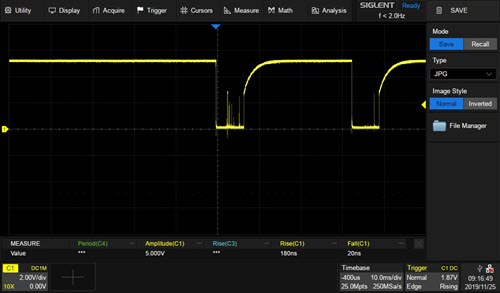

With it, I saw no bouncing. The resulting waveform gives rise and fall times greater than expected from the RC time constant (3.7 ms rise, 1.9 ms fall); presumably there's some internal resistance:

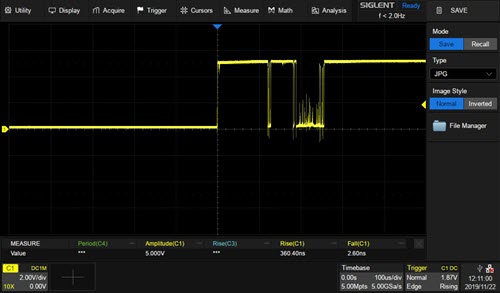

CTS's 288V232R161B2 mechanical encoder gives 4 PPR. 5 ms bounce is specified. No filter circuit is recommended. The worst bounce I saw was about 300 µs.:

CUI Devices's ACZ11BR4E-20KQ01-12C gives 12 PPR. No bounce data is given in the datasheet. Here's the worst I saw - about 5 ms of terror:

The recommended filter circuit is identical to the one Bourns suggests (see above). With it, well, the results were not great:

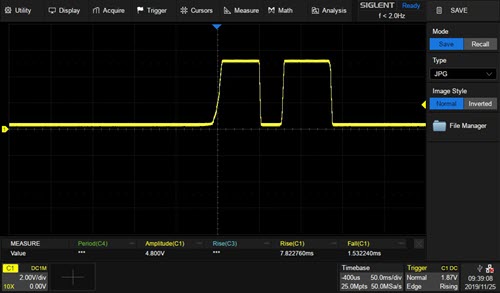

The scope is set to 10 ms/division. Some of those supposedly-filtered zits exceed 2V. Even a Schmitt trigger, like the 74HCT14, will pass these on as valid logic signals. At least the bounces are very narrow. One could write some code that rejects pulses shorter than a ms or so. Just to put this data in perspective, I also tried an optical encoder, expecting clean outputs. And indeed, there was no bouncing. This is the Grayhill 62AG11-L0-P, which sports 32 PPR:

Note the slow rise and fall times, which I saw at times exceeding 8 ms. That is better, however, than the rated 30 ms worst-case numbers. I presume this is an artifact of the optical interrupter swinging into the light beam. Be sure to figure this into your max rotation speed. Assuming 30 ms rise time, and another 30 ms fall time, with 32 PPR the max speed will be under 0.5 rotations/second. I recently rented a Toyota; the radio was almost unusable as turning the tuning knob caused wild and unpredicable results. A clockwise rotation often increased the frequency, as expected, but sometimes the the tuner jumped down or crazily up. One wonders if the engineers used an encoder yet didn't anticipate For ideas about debouncing, see this. |

||||

| Of R&D | ||||

Research and Development. R&D. It's the lifeblood of tech companies, and it's what we engineers do all day, every day. Nonsense. There's no such thing as R&D. There's R, and there's D, and the two are completely separate activities. Research is all about discovering new things. It's the science that ultimately enables the products we build, the metaphorical man-behind-the-curtain pulling the levers to control the machines we create. Research might also involve discovering new algorithms, like new ways to smooth signals or compress data. "New" might mean new to us but not to the world. So we research an idea or a need, and then switch to development mode. The result of research is an approach that one can then implement. Development is taking known ideas and using them to build products. That's the bulk of an engineer's work. We transform an algorithm to something physical, like converting a CRC algorithm to C code, to VHDL inside an FPGA, or to logic components. One of my top ten reasons for failed projects is "bad science," or the inability to separate R from D. When a company starts building a product before really understanding what is being measured the schedule is doomed. Start coding an algorithm without it being sharply defined and, at best, you'll wander aimlessly till, with luck, settling on an approach that works. Research simply can't be scheduled. If you don't believe that, please develop a (realistic) schedule for discovering the cure for cancer. You might be able to guesstimate simple research schedules, like doing a search for a known algorithm, but even that is, in my experience, very difficult to estimate. The first "Eureka" is often followed by disappointment when a little experimenting reveals some fatal flaw, requiring more research to find a better approach. Yet I constantly see teams conflating R and D, leading inevitably to late or failed projects. Sure, there are some projects that necessarily pursue R and D in parallel. But those care rarely be scheduled with any accuracy. What do you think? Have you ever had a project disaster because you were doing R and the same time as D?

|

||||

| Jobs! | ||||

|

Let me know if you’re hiring embedded engineers. No recruiters please, and I reserve the right to edit ads to fit the format and intent of this newsletter. Please keep it to 100 words. There is no charge for a job ad.

|

||||

| Joke For The Week | ||||

These jokes are archived here. Standards, n.: The principles we use to reject other people's code. |

||||

| About The Embedded Muse | ||||

|

The Embedded Muse is Jack Ganssle's newsletter. Send complaints, comments, and contributions to me at jack@ganssle.com. The Embedded Muse is supported by The Ganssle Group, whose mission is to help embedded folks get better products to market faster. We offer seminars at your site offering hard-hitting ideas - and action - you can take now to improve firmware quality and decrease development time. Contact us at info@ganssle.com for more information. |

Click here to unsubscribe from the Embedded Muse, or drop Jack an email.

|

||||

|

You may redistribute this newsletter for non-commercial purposes. For commercial use contact info@ganssle.com. To subscribe or unsubscribe go here or drop Jack an email. |

||||

| Contents | ||||

|

||||

| Editor's Notes | ||||

|

Over 400 companies and more than 7000 engineers have benefited from my Better Firmware Faster seminar held on-site, at their companies. Want to crank up your productivity and decrease shipped bugs? Spend a day with me learning how to debug your development processes. Attendees have blogged about the seminar, for example, here, here and here. I'll present the Better Firmware Faster seminar in Melbourne and Perth, Australia February 20 and 26th. All are invited. More info here. As I noted in a recent blog, I'm cutting back significantly on travel, so this will be my last trip to Australia. Arm has released a free e-book of interest to people integrating Cortex-M parts into their SoCs: System-on-Chip Design with Arm Cortex-M Processors. Be careful what you read. Renesas's new S1JA SoC is based on the Cortex-M23 and appears to be a heck of a part, with just about every peripheral you can imagine. But a writeup on embedded.com reads, in part: "The microcontrollers' ultra-low power extends battery life for battery-operated portable and battery backup applications. The software standby mode consumes only 500 nA to enable 20-year battery-operated applications that spend extended periods in sleep mode." Unless the "battery" is a radioisotope generator the 20-year claim exceeds the shelf-life of the batteries used in portable electronics. Getting years of life from a battery is a hard problem with many subtle issues. For more info see this (though that paper focuses on the CR2032 cell, the concepts scale to most battery types). |

||||

| Quotes and Thoughts | ||||

|

"It is better to define your system up front to minimize errors, rather than producing a bunch of code that then has to be corrected with patches on patches" Margaret Hamilton of Apollo Guidance Computer fame. |

||||

| Tools and Tips | ||||

|

Please submit clever ideas or thoughts about tools, techniques and resources you love or hate. Here are the tool reviews submitted in the past. Thor wrote:

|

||||

| Freebies and Discounts | ||||

|

This month's giveaway is a copy of Embedded Systems World-Class Designs.

Enter via this link. |

||||

| The Rust Programming Language | ||||

|

I'm getting a lot of email about the Rust language, in particular, in using Rust on embedded projects. There's a lot to like about the language. It superficially looks like C/C++. At compile time a borrow-checker tests for memory safety. Basically, each value has an owner. There's only one owner of a variable at a time, and when the owner goes out of scope, the value is dropped. Many people scream at the borrow-checker as it can cause headaches, but users report after a while they learn to abide by Rust's rules, and get a lot of benefit from the memory-safety checks, as it eliminates data races and other common problems. Here's an example factorial program, from the Wikipedia entry: fn factorial(i: u64) -> u64

{

let mut acc = 1;

for num in 2..=i

{

acc *= num;

}

acc

}

Where's the return argument? In Rust, if there's no return statement the last expression is the return value. I find that strangely appealing. The "let" keyword reminds me of the bad old days of Dartmouth BASIC. Rust is used in embedded development, and the main site has a sub-page about this, with examples using a Cortex M processor. While C is a great language for low-level programming and embedded development, it lacks modern features like strong typing (and so much more) that helps create correct programs. The SPARK people call this "correctness by construction." Ada, SPARK, and to a lesser extent Rust enforce rules which lead to safer code. Studies (e.g., Software Static Code Analysis Lessons Learned, Andy German, QinetiQ Ltd., Nov 2003 Crosstalk) show programs in Ada and SPARK have only a fraction of the defects found using C. To my knowledge there's no such data about Rust, but it seems reasonable that Rust code will be less error-prone than C code. I have seen no data on Rust's efficiency (in size and speed), bus suspect it's similar to C. However, as fascinating as it is to learn new languages, there's one place where Rust fails. It's evolving at a rapid pace, and there is no ANSI standard. That's generally not much of a problem in web development or for small embedded projects. But many embedded systems have lives of years and decades. In the railroad industry support has to be guaranteed for 30 years. What will Rust look like a decade or two hence? Will you be able to get a compiler that handles the old dialect? If you have hundreds of thousands of lines of Rust legacy code, reuse might be impossible if all of that is coded using a long-obsolete version. C made its way into the embedded space in the 1980s. Lots of compilers abounded. None were compatible. Remember Manx C? That decade was a veritable Babel of incompatible Cs which was resolved only with the advent of standardization under ANSI C 89/90. As technologists we want the best possible solution. Yet sometimes that has to take second place to business realities. Every engineering effort involves some amount of risk, but we do want to minimize that risk, especially if it could have devastating long-term consequences. Megabucks invested in developing code that can no longer be compiled is a risk that is not, in my opinion, worth taking. I look forward to the day when Rust joins the stable of standardized languages, and have no doubt we'll see that happen in the next decade or so. Standardization efforts move slowly. ANSI spent six years working on the first C standard. |

||||

| Encoder Bouncing | ||||

|

Recent Muses (TEM 384 and TEM 385) had discussions about encoders, which engendered quite a bit of interesting email correspondence. I decided to look at bounce characteristics of a few models. I picked low-cost devices as these are common in controls (e.g., radio volume controls). My focus was (mostly) on mechanical encoders, as it's reasonable to assume these will have significant bounce issues. Bourns's PEC11R-4215F mechanical encoder gives 24 PPR (pulses per revolution). The datasheet specs 2 ms bounce though that is footnoted "Devices are tested using standard noise reduction filters." It's not clear to me if the 2 ms was with or without the filter, but the unit behaved much better than specified. With no filter, this is the worst bouncing I saw:

That's pretty ugly, but the bouncing lasted only about 250 µs. The datasheet recommends this circuit to clean up the noise:

With it, I saw no bouncing. The resulting waveform gives rise and fall times greater than expected from the RC time constant (3.7 ms rise, 1.9 ms fall); presumably there's some internal resistance:

CTS's 288V232R161B2 mechanical encoder gives 4 PPR. 5 ms bounce is specified. No filter circuit is recommended. The worst bounce I saw was about 300 µs.:

CUI Devices's ACZ11BR4E-20KQ01-12C gives 12 PPR. No bounce data is given in the datasheet. Here's the worst I saw - about 5 ms of terror:

The recommended filter circuit is identical to the one Bourns suggests (see above). With it, well, the results were not great:

The scope is set to 10 ms/division. Some of those supposedly-filtered zits exceed 2V. Even a Schmitt trigger, like the 74HCT14, will pass these on as valid logic signals. At least the bounces are very narrow. One could write some code that rejects pulses shorter than a ms or so. Just to put this data in perspective, I also tried an optical encoder, expecting clean outputs. And indeed, there was no bouncing. This is the Grayhill 62AG11-L0-P, which sports 32 PPR:

Note the slow rise and fall times, which I saw at times exceeding 8 ms. That is better, however, than the rated 30 ms worst-case numbers. I presume this is an artifact of the optical interrupter swinging into the light beam. Be sure to figure this into your max rotation speed. Assuming 30 ms rise time, and another 30 ms fall time, with 32 PPR the max speed will be under 0.5 rotations/second. I recently rented a Toyota; the radio was almost unusable as turning the tuning knob caused wild and unpredicable results. A clockwise rotation often increased the frequency, as expected, but sometimes the the tuner jumped down or crazily up. One wonders if the engineers used an encoder yet didn't anticipate For ideas about debouncing, see this. |

||||

| Of R&D | ||||

Research and Development. R&D. It's the lifeblood of tech companies, and it's what we engineers do all day, every day. Nonsense. There's no such thing as R&D. There's R, and there's D, and the two are completely separate activities. Research is all about discovering new things. It's the science that ultimately enables the products we build, the metaphorical man-behind-the-curtain pulling the levers to control the machines we create. Research might also involve discovering new algorithms, like new ways to smooth signals or compress data. "New" might mean new to us but not to the world. So we research an idea or a need, and then switch to development mode. The result of research is an approach that one can then implement. Development is taking known ideas and using them to build products. That's the bulk of an engineer's work. We transform an algorithm to something physical, like converting a CRC algorithm to C code, to VHDL inside an FPGA, or to logic components. One of my top ten reasons for failed projects is "bad science," or the inability to separate R from D. When a company starts building a product before really understanding what is being measured the schedule is doomed. Start coding an algorithm without it being sharply defined and, at best, you'll wander aimlessly till, with luck, settling on an approach that works. Research simply can't be scheduled. If you don't believe that, please develop a (realistic) schedule for discovering the cure for cancer. You might be able to guesstimate simple research schedules, like doing a search for a known algorithm, but even that is, in my experience, very difficult to estimate. The first "Eureka" is often followed by disappointment when a little experimenting reveals some fatal flaw, requiring more research to find a better approach. Yet I constantly see teams conflating R and D, leading inevitably to late or failed projects. Sure, there are some projects that necessarily pursue R and D in parallel. But those care rarely be scheduled with any accuracy. What do you think? Have you ever had a project disaster because you were doing R and the same time as D?

|

||||

| Jobs! | ||||

|

Let me know if you’re hiring embedded engineers. No recruiters please, and I reserve the right to edit ads to fit the format and intent of this newsletter. Please keep it to 100 words. There is no charge for a job ad.

|

||||

| Joke For The Week | ||||

These jokes are archived here. Standards, n.: The principles we use to reject other people's code. |

||||

| About The Embedded Muse | ||||

|

The Embedded Muse is Jack Ganssle's newsletter. Send complaints, comments, and contributions to me at jack@ganssle.com. The Embedded Muse is supported by The Ganssle Group, whose mission is to help embedded folks get better products to market faster. We offer seminars at your site offering hard-hitting ideas - and action - you can take now to improve firmware quality and decrease development time. Contact us at info@ganssle.com for more information. |

Click here to unsubscribe from the Embedded Muse, or drop Jack an email.

|

||||||||

|

You may redistribute this newsletter for non-commercial purposes. For commercial use contact info@ganssle.com. To subscribe or unsubscribe go here or drop Jack an email. |

||||||||

| Contents | ||||||||

|

||||||||

| Editor's Notes | ||||||||

|

Happy Beethoven's birthday! Some HP SSDs "stop running after the 32,768-hour mark." The citation is from an article in Electronic Design. The language is a bit muddy; I expect they fail as the time rolls over from 32,767 to 32,768 hours. Bugs are all-too-common but consider this: That's almost four years. No reasonable amount of testing would uncover the problem. While test is critical, it's inadequate. Without access to the code it's impossible to be certain, but I suspect even achieving 100% test coverage would not have picked up the problem. Test is just one of many filters needed to insure correct code. Over 400 companies and more than 7000 engineers have benefited from my Better Firmware Faster seminar held on-site, at their companies. Want to crank up your productivity and decrease shipped bugs? Spend a day with me learning how to debug your development processes. Attendees have blogged about the seminar, for example, here, here and here. I'll present the Better Firmware Faster seminar in Melbourne and Perth, Australia February 20 and 26th. All are invited. More info here. As I noted in a recent blog, I'm cutting back significantly on travel, so this will be my last trip to Australia. It's a beautiful country with great people, but a long way from my homestead in Maryland. |

||||||||

| Quotes and Thoughts | ||||||||

|

Re: Wilbur Wright: "Wilbur was a man who established a goal with care, then never lost sight of it. He was the perfect engineer - isolating a basic problem, defining it in the most precise terms, and identifying the missing bits of information that would enable him to solve it. Other students of the subject lost themselves in a welter of confusing details; they were lured into extraneous, if fascinating, blind alleys that led away from the basic problem." From the book The Bishop's Boys by Tom Crouch. |

||||||||

| Tools and Tips | ||||||||

|

Please submit clever ideas or thoughts about tools, techniques and resources you love or hate. Here are the tool reviews submitted in the past. Mat Bennion raised one of the issues we hear about from time to time with the use of C:

In a time when so many articles in the trade press are thinly-disguised press releases, it's important to acknowledge those pushing back against this sort of uber-marketing. Bill Schweber's articles in Electronic Design consistently provide information of use to engineers. They typically describe how some component or circuit works, like this week's excellent piece that describes flyback circuits. |

||||||||

| Freebies and Discounts | ||||||||

|

Curt Bruns won the power supply in the November contest. This month's giveaway is a copy of Embedded Systems World-Class Designs.

Enter via this link. |

||||||||

| DO-178C On Requirements | ||||||||

|

It's believed, until the recent 737-MAX crashes, that no one had ever lost a life in a commercial aircraft due to a software problem. Why is this? No one really knows. All commercial aircraft software in the USA is crafted to DO-178C. Is it the use of this standard, or is it a safety culture that is willing to embrace the burdensome regs? Regardless, few industries regularly achieve the high quality of code done to DO-178C. Harold Kraus sent in the following about the importance of requirements in avionics. But first, a couple of definitions for those unfamiliar with DO-178C:

Here's Harold's write-up:

|

||||||||

| Benchmarking Firmware Teams | ||||||||

|

How does your team compare to others in the industry? Is it world-class, or sub-par? Benchmarking is the practice of comparing some aspect of a business with other companies in the same industry. For instance, a business might average 46 days to collect a receivable. What does that mean? If the industry average is 35 days, 46 is nothing to brag about. If 80% of their competitors do worse, then 46 is a great number. It's likely going to be hard to gain much improvement. I've advocated benchmarking firmware teams for many years. Alas, it's hard to get good numbers, and the standard deviations are high. But we do have some data. In my Better Firmware Faster class I stress the importance of engineering with numbers. As David Aikin said: "Engineering is done with numbers. Analysis without numbers is only an opinion." For instance, most teams average a 5 to 10% defect rate after getting a clean compile before any testing starts. Worst-in-class engineers generate 250 defects per KLOC. There's no measurable difference between C and C++. So for a 10KLOC project figure on chasing 500 to 1,000 problems. Ever wonder why projects run late? Clearly these numbers are abysmal. Cut them by half and the schedule will improve dramatically. Ada teams are about an order of magnitude better, and SPARK developers crush even Ada. Where do bugs come from? This table shows defects/KLOC for a poorly-performing team, and one rated at Capability Maturity Level 3, considered a pretty disciplined outfit:

And here's where defects are removed:

Defect Removal Efficiency (DRE) is one of those tortured terms academics love. It's merely the percentage of defects removed during engineering and up to 90 days post-initial delivery. You'd hope for 100%. Here's where the industry stands. "Bugs/KLOC" is the number of shipped bugs per thousand lines of code:

Poor quality teams tend to rely mostly on test to find defects. Capers Jones identifies over 60 ways to minimize these, though no one does or should use all of those. I view this as a series of filters, each stage removing some percentage of problems. It has been shown that test, by itself, typically finds only 50%. For more numbers Capers Jones' books are a great resource. The sadly-defunct Crosstalk Magazine was also a valuable resource. How does your team measure up? |

||||||||

| Rust Redux | ||||||||

|

Muse 387's comments about the Rust programming language generated a lot of discussion. Nick P's thoughts were useful:

Tock is an RTOS written in Rust. The Case for Writing a Kernel in Rust is a worthwhile paper about how Rust is a good choice for RTOS work, though I stand by my thoughts in Muse 387. |

||||||||

| More on R&D | ||||||||

A number of people responded to last issue's comments on R&D. Charles Manning wrote:

From Mike Davis:

Rob Milne commented:

Emil Imrith had a suggestion:

|

||||||||

| Jobs! | ||||||||

|

Let me know if you’re hiring embedded engineers. No recruiters please, and I reserve the right to edit ads to fit the format and intent of this newsletter. Please keep it to 100 words. There is no charge for a job ad.

|

||||||||

| Joke For The Week | ||||||||

These jokes are archived here. bug, n: A son of a glitch. |

||||||||

| About The Embedded Muse | ||||||||

|

The Embedded Muse is Jack Ganssle's newsletter. Send complaints, comments, and contributions to me at jack@ganssle.com. The Embedded Muse is supported by The Ganssle Group, whose mission is to help embedded folks get better products to market faster. We offer seminars at your site offering hard-hitting ideas - and action - you can take now to improve firmware quality and decrease development time. Contact us at info@ganssle.com for more information. |

Click here to unsubscribe from the Embedded Muse, or drop Jack an email.

|

||||||||

|

You may redistribute this newsletter for non-commercial purposes. For commercial use contact info@ganssle.com. To subscribe or unsubscribe go here or drop Jack an email. |

||||||||

| Contents | ||||||||

|

||||||||

| Editor's Notes | ||||||||

|

Happy Beethoven's birthday! Some HP SSDs "stop running after the 32,768-hour mark." The citation is from an article in Electronic Design. The language is a bit muddy; I expect they fail as the time rolls over from 32,767 to 32,768 hours. Bugs are all-too-common but consider this: That's almost four years. No reasonable amount of testing would uncover the problem. While test is critical, it's inadequate. Without access to the code it's impossible to be certain, but I suspect even achieving 100% test coverage would not have picked up the problem. Test is just one of many filters needed to insure correct code. Over 400 companies and more than 7000 engineers have benefited from my Better Firmware Faster seminar held on-site, at their companies. Want to crank up your productivity and decrease shipped bugs? Spend a day with me learning how to debug your development processes. Attendees have blogged about the seminar, for example, here, here and here. I'll present the Better Firmware Faster seminar in Melbourne and Perth, Australia February 20 and 26th. All are invited. More info here. As I noted in a recent blog, I'm cutting back significantly on travel, so this will be my last trip to Australia. It's a beautiful country with great people, but a long way from my homestead in Maryland. |

||||||||

| Quotes and Thoughts | ||||||||

|

Re: Wilbur Wright: "Wilbur was a man who established a goal with care, then never lost sight of it. He was the perfect engineer - isolating a basic problem, defining it in the most precise terms, and identifying the missing bits of information that would enable him to solve it. Other students of the subject lost themselves in a welter of confusing details; they were lured into extraneous, if fascinating, blind alleys that led away from the basic problem." From the book The Bishop's Boys by Tom Crouch. |

||||||||

| Tools and Tips | ||||||||

|

Please submit clever ideas or thoughts about tools, techniques and resources you love or hate. Here are the tool reviews submitted in the past. Mat Bennion raised one of the issues we hear about from time to time with the use of C:

In a time when so many articles in the trade press are thinly-disguised press releases, it's important to acknowledge those pushing back against this sort of uber-marketing. Bill Schweber's articles in Electronic Design consistently provide information of use to engineers. They typically describe how some component or circuit works, like this week's excellent piece that describes flyback circuits. |

||||||||

| Freebies and Discounts | ||||||||

|

Curt Bruns won the power supply in the November contest. This month's giveaway is a copy of Embedded Systems World-Class Designs.

Enter via this link. |

||||||||

| DO-178C On Requirements | ||||||||

|

It's believed, until the recent 737-MAX crashes, that no one had ever lost a life in a commercial aircraft due to a software problem. Why is this? No one really knows. All commercial aircraft software in the USA is crafted to DO-178C. Is it the use of this standard, or is it a safety culture that is willing to embrace the burdensome regs? Regardless, few industries regularly achieve the high quality of code done to DO-178C. Harold Kraus sent in the following about the importance of requirements in avionics. But first, a couple of definitions for those unfamiliar with DO-178C:

Here's Harold's write-up:

|

||||||||

| Benchmarking Firmware Teams | ||||||||

|

How does your team compare to others in the industry? Is it world-class, or sub-par? Benchmarking is the practice of comparing some aspect of a business with other companies in the same industry. For instance, a business might average 46 days to collect a receivable. What does that mean? If the industry average is 35 days, 46 is nothing to brag about. If 80% of their competitors do worse, then 46 is a great number. It's likely going to be hard to gain much improvement. I've advocated benchmarking firmware teams for many years. Alas, it's hard to get good numbers, and the standard deviations are high. But we do have some data. In my Better Firmware Faster class I stress the importance of engineering with numbers. As David Aikin said: "Engineering is done with numbers. Analysis without numbers is only an opinion." For instance, most teams average a 5 to 10% defect rate after getting a clean compile before any testing starts. Worst-in-class engineers generate 250 defects per KLOC. There's no measurable difference between C and C++. So for a 10KLOC project figure on chasing 500 to 1,000 problems. Ever wonder why projects run late? Clearly these numbers are abysmal. Cut them by half and the schedule will improve dramatically. Ada teams are about an order of magnitude better, and SPARK developers crush even Ada. Where do bugs come from? This table shows defects/KLOC for a poorly-performing team, and one rated at Capability Maturity Level 3, considered a pretty disciplined outfit:

And here's where defects are removed:

Defect Removal Efficiency (DRE) is one of those tortured terms academics love. It's merely the percentage of defects removed during engineering and up to 90 days post-initial delivery. You'd hope for 100%. Here's where the industry stands. "Bugs/KLOC" is the number of shipped bugs per thousand lines of code:

Poor quality teams tend to rely mostly on test to find defects. Capers Jones identifies over 60 ways to minimize these, though no one does or should use all of those. I view this as a series of filters, each stage removing some percentage of problems. It has been shown that test, by itself, typically finds only 50%. For more numbers Capers Jones' books are a great resource. The sadly-defunct Crosstalk Magazine was also a valuable resource. How does your team measure up? |

||||||||

| Rust Redux | ||||||||

|

Muse 387's comments about the Rust programming language generated a lot of discussion. Nick P's thoughts were useful:

Tock is an RTOS written in Rust. The Case for Writing a Kernel in Rust is a worthwhile paper about how Rust is a good choice for RTOS work, though I stand by my thoughts in Muse 387. |

||||||||

| More on R&D | ||||||||

A number of people responded to last issue's comments on R&D. Charles Manning wrote:

From Mike Davis:

Rob Milne commented:

Emil Imrith had a suggestion:

|

||||||||

| Jobs! | ||||||||

|

Let me know if you’re hiring embedded engineers. No recruiters please, and I reserve the right to edit ads to fit the format and intent of this newsletter. Please keep it to 100 words. There is no charge for a job ad.

|

||||||||

| Joke For The Week | ||||||||

These jokes are archived here. bug, n: A son of a glitch. |

||||||||

| About The Embedded Muse | ||||||||

|

The Embedded Muse is Jack Ganssle's newsletter. Send complaints, comments, and contributions to me at jack@ganssle.com. The Embedded Muse is supported by The Ganssle Group, whose mission is to help embedded folks get better products to market faster. We offer seminars at your site offering hard-hitting ideas - and action - you can take now to improve firmware quality and decrease development time. Contact us at info@ganssle.com for more information. |

Click here to unsubscribe from the Embedded Muse, or drop Jack an email.

|

||||

|

You may redistribute this newsletter for non-commercial purposes. For commercial use contact info@ganssle.com. To subscribe or unsubscribe go here or drop Jack an email. |

||||

| Contents | ||||

|

||||

| Editor's Notes | ||||

|

Over 400 companies and more than 7000 engineers have benefited from my Better Firmware Faster seminar held on-site, at their companies. Want to crank up your productivity and decrease shipped bugs? Spend a day with me learning how to debug your development processes. Attendees have blogged about the seminar, for example, here, here and here. Engineering changes at an accelerating pace. The boss wants more bug-free code, today. Tomorrow he'll want even more in the same time-frame. Are you on top of the best ways to deliver it? Some tell me they just don't have time to attend seminars. I'm reminded of this:

It is important to fight today's engineering battle. But the war will be lost if you don't find better ways to win. This is what my one-day Better Firmware Faster seminar is all about: giving your team the tools they need to operate at a measurably world-class level, producing code with far fewer bugs in less time. It's fast-paced, fun, and uniquely covers the issues faced by embedded developers. I'll present the Better Firmware Faster seminar in Melbourne and Perth, Australia February 20 and 26th. All are invited. More info here. The early registration discount ends today. As I noted in a recent blog, I'm cutting back significantly on travel, so this will be my last trip to Australia. It's a beautiful country with great people, but a long way from my homestead in Maryland. Jack's latest blog: A Lack of Forethought |

||||

| Quotes and Thoughts | ||||

|

I never give anyone hell. I only tell the truth. They think it's hell. Harry S. Truman |

||||

| Tools and Tips | ||||

|

Please submit clever ideas or thoughts about tools, techniques and resources you love or hate. Here are the tool reviews submitted in the past. |

||||

| Freebies and Discounts | ||||

|

This month's giveaway is a Cypress CY8KIT-044 PSoC 4 M-series Pioneer kit.

Enter via this link. Brian Cuthie reports that the schematic editor/simulation software Micro-Cap is now free. See this. |

||||

| On Requirements Documents | ||||

|

How long are your requirements documents? How complete are they? Getting hard data is notoriously difficult in the software world. Capers Jones probably has more than anyone. He stresses the large standard deviation, but makes it clear that one can gain some insight from it. I view the data as an impressionist painting, where the outlines might be fuzzy, but one can still make out the general shape of things. The following table is derived from data in Jones' The Economics of Software Quality. It shows how many pages of requirements are found for various-sized projects. The "Requirements Completeness" column illustrates all-to-pathetically how short those pages are of the delivered functionality.

Jones uses function points instead of lines of code. Most of us are uncomfortable with function points, so I've converted them to lines of C code using the generally-accepted average of one FP being 130 lines of C. Playing with the numbers, for 100% completeness you'd need about one page of requirements documentation for every ten lines of code. It's not clear if a "page" means 500 words, or perhaps just a sentence or two, with perhaps each requirement standing proudly on its own page. What do your numbers look like? |

||||

| More New Years Resolutions | ||||

|

Vlad Z sent more New Year's resolutions:

|

||||

| On E-Voting | ||||

|

Later this year the US will chose a new president. But who will make that choice? I last wrote about electronic voting machines in the election year of 2008. Twelve years later little has changed. Vermin the world over will exploit any computer weakness to extort tens of thousands of dollars from the unsuspecting populace. Those are pretty puny stakes compared with the presidential election, which will consume billions of dollars of campaign funds and will shape the direction of the most powerful nation on the planet for at least four years. So how did we react? By acquiring voting machines with many known security flaws, developed without using best engineering practices, whose code is proprietary, and that use hacker-friendly operating systems. In effect, the government, by making these purchasing decisions, sanctioned a "we're the government, you can trust us" appeal to the electorate. Ironically, the citizenry has never trusted the government less than in recent years. We know how to build reliable software systems. We know how to build secure software systems. We decided not to. How dumb is that? Democracy is hard. We citizens have to be involved. We need to hold our elected officials accountable, and toss them out when they fail to meet our standards. That requires we trust the integrity of the ballot box. E-voting travails are not new; ballot-stuffing is as old as the Republic. The difference is that now it may be possible to stuff millions of votes with a few clicks. I believe that e-voting holds the promise of eliminating compromised elections. But not with the approaches used now. I'm sickened to read of various commissions demanding that vendors add printers to their machines. That's does nothing to prove that each vote is recorded properly. The printer could show one candidate and record another. And the voting machine itself is not the issue: it's the entire system, including the computers that hold the databases, which are even more attractive targets for bad actors. We citizens must demand a system that works. That requires the following:

Will this happen? I doubt it. Conspiracy theorists probably feel the overlords who control the government want to have hackable elections. But I suspect there's more truth in: Never ascribe to malice, that which can be explained by incompetence. |

||||

| The Secret of My Success | ||||

The blue light of the TV flickered on the blank wall, but it went unnoticed by me as I slumped in my old armchair. It had been a bad week. She left on Monday, screaming that she couldn't take all of the equipment piled everywhere. Me, I thought that old Tek 545 was a collector's item, an antique. Sure, the dust was pretty bad, but you can bet we were the only couple in town with a living room populated by old scopes and CP/M machines. Yeah, I do mess up some times, like that time my homebrew furnace controller burped and drove the house to 115 degrees when we were gone for the weekend. Hey, I never liked those pets anyway, and the smell did eventually come out of the carpets. Pretty much. I mean, it was just a little software bug; we all have those! And there was the fire. Yeah, next time I'll put a bigger heat sink on the power supply. I admit it - I learned a lesson. The scorch marks on her dresses don't really look all that bad. I reached for another bag of chips as the chair groaned a bit more. One of these days I'm gonna have to work off some of the excess pounds. A decade spent in the lab drinking Jolt and munching fries had taken its toll. Despite the flab I still know calculus and can program in C; surely a dream dude for any discerning woman. I bet I could wow them at the local watering hole with my great stories about TCP/IP! Well, this is Silicon Valley after all, where relationships, jobs and careers are measured in milliseconds and loyalty doled out by the microgram. Electronics is a dog-eat-dog business and I'm an old hand at crawling out from the wreckage. Like that last startup I worked for. I told 'em we'd get that product out the door, eventually anyway. We woulda survived if that idiot president just got another couple of mil of venture capital. For a while at least. Ya know, maybe it was losing that job that ticked her off. I figure, what's the big deal? She should be used to this by now. Check out my resume - it shows lots of experience at lots of places. No one can beat this! I picked up the phone but heard only the accusing silence of a non-payment disconnection. No matter. Time to find another company looking for my embedded expertise. There's a startup a minute here, pigeons ripe for picking. I clumped out of the trailer's front door and found Big Al, the usual wild look in his eyes, mouth working hard on this morning's sugar raised, the white powder spotting his beard.� "Al, buddy, you're outa work too, huh? How's the wife and kids?" "Kids? Kids? Yeah, come to think of it I did notice some little people living with me. I wonder where they came from? Check this out." With that he shoved a coffee-stained fragment of the San Jose Mercury News into my hands. I quickly took in the circled want ad. "ENGINEERs � microprocessor savvy designers and programmers needed. C, FPGAs, assembly a plus. Exciting opportunity for a motivated developers in a new high-growth company." A slow smile spread across my face. Here was our pigeon; I was already mentally spending the signing bonus. That afternoon, T-shirts cleaned and pressed, with most of the donut detritus hurriedly wiped from Al's beard, we met with the president of Galaxar Enterprises. Yep, just as usual, this man was the typical harried executive desperate for people, so desperate he had neither the time nor resources to do much of a background check. Not that my background is so terrible; it's just that there's so much of it. "You know C? Schematic capture? What's the last project you worked on?" he mumbled, looking at his watch while the cell pinged an urgent tune. "We did that Internet cappuccino maker for Kitchen Services; you must have read about it in the press. Yep, that puppy had a RISC-V based coffee engine with 10 gigs of RAM�" "Didn't they go Chapter 7?", he interrupted, interested� now. "Trust me on this. The boss was an idiot. He just didn't understand how much compute power we needed to blend the perfect cuppa joe. That sucker could crank some coffee, believe me. If they hadn't been so stuck on the cost of goods we coulda cleaned up the cappuccino market. We were practically done with development when the SEC raided us." "OK, OK, look, when can you start? Now? Don't you guys ever shave? Hell, just sit here and Bob will tell you what to do." Bob, engineering VP, was one of those snotty-nosed brats with a degree and an attitude. "We're building a new marine VHF radio for the recreational boating market. That means there are three main design parameters. First, the unit must be totally sealed to insure it's waterproof. Second, the sell price can't exceed $250. And obviously the unit must be simple enough that even the most casual boater can use it." He went on to tell us how we were going to design the product. Us! Can you imagine? As if I don't understand project planning, structured design, discipline design, and all of that utter crap. Me, I prefer to skip all of that non-productive nonsense and just bang it out. I zoned out, the drone of Bob's voice barely noticeable, nodding at the right time while planning my next move. Clearly it was time for the old end-run. Saturday night Al and I marched into the president's office. "Herb," I started, "we know you're running out of venture money and an IPO is at least a year away. Bob's planning to spend another three months just doing preliminary design. Whatdoya want, a design or a product? Trust me on this � we can pound out a design in a week, max, and then get the radio done in no time." Herb's eyes gleamed. It seems that he, too, was frustrated by Bob's methodical approach to engineering. This valley is the land of Steve Jobs, where unbridled passion and hope fuels the dream of tomorrow's big score. Discipline? Bah. Just lemme at a problem and I'll get it done. With a bit more prodding Herb agreed that this project was so important he'd give it skunk-works treatment, get Bob off of our backs, and let us report directly to his president's office. The week sped by like a read from cache memory. Al slouched into my cubicle, let out a long, satisfying-sounding belch, and asked "didn't we promise Herb a spec or something?" Right! Never let the boss, down, that's my motto. Unless there's a good reason, of course. "Sure, look, just grab those header files we've been working on and edit a bit of descriptive stuff at the beginning. They'll never read it all anyway. If he complains we'll tell 'em not only is the spec done, we've incorporated it into the firmware. How can he get upset if he sees we're already coding?" Herb swallowed our header files hook, line and sinker. He's thrilled that we're already cranking out software, and giddily reported our progress to the venture capitalists. I think they're already mentally spending their IPO profits. Bob is muttering vague threats, but he's been squeezed into the user-interface group.� He wants Al and I to take on that new college grad, Marty. We're supposed to show him how to get projects done. It's� not all bad; the kid has a car so can get us beers and carry-out. The secret to success in this business is to look busy, keep a prototype in a state that looks like it has some level of functionality, and always agree with the boss.� And you can't act like you have a personal life when battling a schedule! Heck, after just three days on the job Marty asked if he could leave at 5 to celebrate his first anniversary. I straightened him out. "Kid, trust me on this. We all go through one or two starter marriages, you know, no kids, no property, no regrets. Don't take it too seriously. Now let's order a pizza and get back to work." It was probably a good thing that I turned off the switchboard that night, so he wouldn't get distracted by all of those frantic calls from home. And that kid did need some attention. I caught him late one night doing a spell check on his comments! Somehow he missed the fact that a ship date loomed; comments are always the first thing to go. "Kid, trust me on this. Never include a comment that will help someone else understand your code. If they understand it, they don't need you." I think he gets the picture now. As time moved on we started having trouble fitting the binary image into the CPU's address space. "This always happens", I reassured Herb, "them 16 bitters just can't handle the sort of code we're cranking out for you. Look, we'll just stuff a bigger part in there this afternoon. No problemo; I've done this a million times." Big Al's eyes lit up when I suggested we look into a 64 bit processor. "I've got just the ticket. There's one I've been itching to try; it's totally reconfigurable, you can even define your own instruction set. Man, this is gonna look great on my resume!" Ah, resume fodder, the grease of the industry. Herb didn't seem to concerned about the increased cost of goods � at least he wasn't asking any questions � so I set out trying to find some way to cool the sucker. With luck a big old heat sink and decent-sized fan might be adequate. Jeez, maybe I'll use the next size up; those burnt dresses still haunt me at times. We optimized the instruction set on the CPU to play DoomStar III at awesome speeds. The best part of using a custom architecture was that I got to port the entire GNU toolchain to our chip. That compiler sure is tricky! First time I'd ever fiddled with a code generator, so it naturally took a bit longer than planned to get working � mostly � tools. As the weeks passed Herb got noticeably more antsy, checking on our progress on a daily, and then hourly, basis. This always happens, and is a sign that the old cash reserve is evaporating. I started running to the bank the minute paychecks came out. No one's gonna stick me with bouncing paper! Been there, done that. Bob � remember Bob? � strolled into the lab one afternoon to check on our progress. It seems the fool had actually invested his own money into the company! He's correspondingly annoying about what we do, even though my end-run had gotten him off the project months before. Oddly, he seemed upset about the cooling fan. "This thing has got to be totally sealed, so no water gets in!" he whined. "Yeah, yeah, just mount it in a dry place or something", I replied. "I can't be bothered with that sort of stuff. You know how much power this sucker uses?" These company men are all stress puppies. Not me; I'll be going strong when he suffers his first mid-30s myocardial infarction. Christmas rolled around � or was it Easter? I dunno, we were plenty busy chasing down bugs and making feature changes. Bob's paycheck bounced. I knew that Herb had been doing some fancy footwork to keep things afloat, but when everyone in accounting quit, complaining about insolvency or something, the standard exodus began. As usual, engineering remained untouched by the various rounds of layoffs. They needed the products we make to survive. I love this field! This seemed like a great time for a two week vacation, though Marty seemed almost hysterical that I'd take off now. "Kid, trust me on this. Never complete a project on time. If you do, they will think it was easy and anyone can do it and they don't need you. Now I'm outa here for a while. Look busy and we'll sort it all out when I get back." I got back, more or less sober but feeling great, to find the front door padlocked and a sheriff standing guard. Marty, skulking in a dark corner, grabbed my arm and moaned that he couldn't build the code at all while I was away. It seems he had trouble locating all of the source. "Kid, trust me on this. Never archive all the sources necessary to build a binary. Always hide a few on your own disk. If they can build your binary, they don't need you. What do they teach you in college, anyway?" He said the creditors got fed up and were demanding their money. Half the employees were suing because their paychecks bounced. A satisfied grin spread across my face as I recalled beating the rest of those idiots to the bank. Marty shrieked that Herb was suing all of us in engineering for not meeting promised dates, specs, or features. "Kid, trust me on this. They always sue. That's why I own nothing. What do they think they'll get, my trailer? The bank owns that!" Well, it seems my two week holiday might extend itself a bit. No worries there! After such a tough project I needed a break. It's time to sleep in for a while, build up those reserves. Days later an awful booming interrupted my sleep. "My god, it's not even noon!" I shouted, "go away". The door slammed open and Big Al loomed over me. "Check this out." He unwrapped the newspaper from around his BLT and handed me a section from the want ads. Yep, old Al was right on top of things again. Another startup, as usual desperate for a pair of gurus like us, no doubt willing to hire at any price. A harried president briefly interviewed the two of us, asking lots of questions about our most recent experience. We gave them the scoop on the VHF radio, but had to parry his request for references. "Sorry � they went out of business. Shame, that. There's no one there you can call. But we built a hell of a radio for those guys. It's too bad management was so screwed up they folded. Hey, it happens all the time in this industry." "But trust me on this � you need a graybeard like me to mentor your young engineers, and to get this project out now! I'm ready to start coding today. What is it we're building?" |

||||

| This Week's Cool Product | ||||

Bob Paddock sent in a link to an article about a new-fangled battery. The key specs:

It's SMT-compatible in an EIA 1812 package. The article doesn't list a price (a practice that is unacceptable), but Digi-Key lists these at $8.30 in small quantities. While this is an interesting part, with only 100 µAh of capacity and the relatively high cost, I'm not sure where such a part makes sense. Note: This section is about something I personally find cool, interesting or important and want to pass along to readers. It is not influenced by vendors. |

||||

| Jobs! | ||||

|

Let me know if you’re hiring embedded engineers. No recruiters please, and I reserve the right to edit ads to fit the format and intent of this newsletter. Please keep it to 100 words. There is no charge for a job ad.

|

||||

| Joke For The Week | ||||

These jokes are archived here. Tomislav Razov sent this: Changing random stuff until your program works is "hacky" and "bad coding practice". But if you do it fast enough it is "Machine learning" and pays 4x your current salary. |

||||

| About The Embedded Muse | ||||

|

The Embedded Muse is Jack Ganssle's newsletter. Send complaints, comments, and contributions to me at jack@ganssle.com. The Embedded Muse is supported by The Ganssle Group, whose mission is to help embedded folks get better products to market faster. We offer seminars at your site offering hard-hitting ideas - and action - you can take now to improve firmware quality and decrease development time. Contact us at info@ganssle.com for more information. |

Click here to unsubscribe from the Embedded Muse, or drop Jack an email.

|

||||

|

You may redistribute this newsletter for non-commercial purposes. For commercial use contact info@ganssle.com. To subscribe or unsubscribe go here or drop Jack an email. |

||||

| Contents | ||||

|

||||

| Editor's Notes | ||||

|

Over 400 companies and more than 7000 engineers have benefited from my Better Firmware Faster seminar held on-site, at their companies. Want to crank up your productivity and decrease shipped bugs? Spend a day with me learning how to debug your development processes. Attendees have blogged about the seminar, for example, here, here and here. Engineering changes at an accelerating pace. The boss wants more bug-free code, today. Tomorrow he'll want even more in the same time-frame. Are you on top of the best ways to deliver it? Some tell me they just don't have time to attend seminars. I'm reminded of this:

It is important to fight today's engineering battle. But the war will be lost if you don't find better ways to win. This is what my one-day Better Firmware Faster seminar is all about: giving your team the tools they need to operate at a measurably world-class level, producing code with far fewer bugs in less time. It's fast-paced, fun, and uniquely covers the issues faced by embedded developers. I'll present the Better Firmware Faster seminar in Melbourne and Perth, Australia February 20 and 26th. All are invited. More info here. The early registration discount ends January 20. As I noted in a recent blog, I'm cutting back significantly on travel, so this will be my last trip to Australia. It's a beautiful country with great people, but a long way from my homestead in Maryland. Jack's latest blog: How I Write Code. A recent article in Electronic Design spotlights crashing DRAM and NAND prices. The latter are off 79% from their mid-2017 numbers. But a stunning graph later in the article shows that 1 GB of DRAM cost around $70k in 1991! It's around $3 today. I don't know how accurate that $70k number is, but even if it's off by an order of magnitude that shows astonishing progress in electronics over the last three decades. |

||||

| Quotes and Thoughts | ||||

|

Coding is "90% finished" for half the total coding time. Fred Brooks |

||||

| Tools and Tips | ||||

|

Please submit clever ideas or thoughts about tools, techniques and resources you love or hate. Here are the tool reviews submitted in the past. John Carter likes the D language, and he also included a useful link to Stroustup's and Sutter's C++ guidelines:

Interestingly, D does not support 8 or 16 bit processors. From the overview page: "No consideration is given in D for mixed near/far pointers and all the machinations necessary to generate good 16 bit code. The D language design assumes at least a 32 bit flat memory space and supports 64 bit as well." I assume that means no MMU or MPU, which is a shame, as these resources can be useful in preventing complete system crashes. |

||||

| Freebies and Discounts | ||||

|

This month's giveaway is a Cypress CY8KIT-044 PSoC 4 M-series Pioneer kit.

Enter via this link. Percepio is giving away one-year licenses for their TraceAlyzer debugging tool. I've played with it and find it a great way to visualize how your code interacts with the RTOS (many RTOSes supported). The giveaway is not exactly free - you have to send a description of what you'll do with it, and follow-up with a story about solving the problem. More info here. I image the story could be pretty short. Not a freebie for Muse readers, but here's an astonishing giveaway: a business card that runs Linux. Production cost: $3 in low volumes. Linux for three bucks? For all the sturm and drang in the political news, sometimes we need to take a step back and just be amazed at how cool things are. Thanks for Martin Buchanan for sending the link. |

||||

| New Year's Resolutions for Firmware Developers | ||||

|

Happy New Year! I thought it would be fun to Google for New Year's resolutions for software people. Most of the results were things like "share more," "work with the community," "contribute to open source," "cut back to one quart of whiskey per day," and the like. Nice thoughts, but what technical resolutions are worthwhile? First, I don't like aspirations like "work harder at..." That's impossible to measure. Without numbers, we're lost in a fog. Without numbers, we can't understand if we're improving. Without numbers, we don't know how we measure up against others (e.g., am I in the bottom quartile of developers?). And, as Harry Roberts demonstrates in Quality is Personal, "trying harder" rarely works. So here are some thoughts:

|

||||

| Principles For Interfacing With Humans | ||||

|

John Carter sent an excerpt from Standard Practice for Human Engineering Design for Marine Systems, Equipment and Facilities. These notions should be embraced by all engineers. Humans are flawed, which this standard addresses explicitly. But first, a story. I read (somewhere recently, maybe in the Smithsonian's Air and Space magazine) that during WWII B-17s crashed on landing far more often than one would expect. Turns out, the gear and flaps levers were located near each other and looked similar. Tired, stressed pilots would mix up the controls. Relocating and changing the appearance eliminated those sorts of accidents. The moral: design with real people in mind. Here are the practices: 4.2 Principles of Human Behavior: 4.2.1 There are basic principles of human behavior that control or influence how each person performs in their workplace. Some of these behaviors are culturally derived, while others are general and uniform across all cultures and geographical regions of the world. These behaviors influence a person's physical, social, and psychological approach toward the work they do and how safely they do that work. Failure to satisfy these behavioral principles in the design of a ship or maritime structure can encourage, or even coerce, maritime personnel into taking unsafe risks in their everyday activities. It is, therefore, imperative that designers of ships and maritime equipment, systems, and facilities know these principles to provide a safe and efficient workplace for maritime personnel. 4.2.2 These principles include: 4.2.2.1 If the design of the ship or maritime facility is considered to be unsafe or inefficient by the crew, it will be modified by the users, often solving the initial problem but introducing others that may be as bad, or worse, than the original. 4.2.2.2 Equipment design shall be such that it encourages safe use, that is, does not provide hardware and software that can be used in an unsafe manner. 4.2.2.3 If the equipment or system is not designed to operate as the users' cultural and stereotypical expectations lead them to think that it will operate, the chance for human error is significantly increased. 4.2.2.4 If equipment or systems are perceived by operators/maintainers to be too complex or require more effort to operate or maintain than they believe is necessary, they will always look for a "shortcut." Further, this "shortcut" may be perceived as being safe when it is not. 4.2.2.5 No amount of training, company or organizational policy, threats of retaliatory action, warning notes in a technical manual or training guide, or pleading with personnel to be safe on the job can overcome poor design that encourages, leads, or even coerces personnel into unsafe acts on the job. The most efficient way to prevent unsafe design from contributing to an accident is to eliminate the unsafe design. 4.2.2.6 Equipment users tend to be very unimaginative when it comes to identifying unsafe features and they do not visualize the consequences of unsafe acts. Therefore, do not expect that an "obviously dangerous" task will always be recognized as such by every user. 4.2.2.7 Designers shall consider the possibility for human error and design equipment so that incorrect use (deliberate or accidental) will result in little or no harm to the user. 4.2.2.8 Equipment operators and maintainers tend to make guesses as to what a label, instruction, or operational chart states if it is not complete, legible, readable, and positioned correctly. 4.2.2.9 Designers and engineers shall never use themselves as the standard against which a particular design is evaluated. People come in many shapes, sizes, mental capacities, and capabilities. Therefore, design for the full range of potential users, physically, mentally, and socially. 4.2.2.10 People shall be protected against themselves. Designers cannot create an unsafe piece of equipment or system and expect the users to assume full responsibility for its safe use. 4.2.2.11 Ease of equipment maintenance affects the equipment's reliability, that is, the harder it is to be maintained, the less it will be maintained. 4.2.2.12 Equipment designed to require multiple operators working together simultaneously increases the likelihood of operator errors. 4.2.2.13 Operational/maintenance procedures shall be clear, definitive, and comprehensive, otherwise, they will be misinterpreted or ignored. 4.2.2.14 Structural items such as piping, cable trays, or any other item that appears strong enough to be used by a person to hold onto or stand on, and is placed in a convenient location to use for that purpose, will eventually be used for that purpose. 4.2.2.15 Humans expect consistency in the design and arrangement of their workplace. Therefore, if that workplace, or any part thereof, appears in more than one place in their work environment, it is expected to be located and look the same way at every location. 4.2.2.16 When controls and displays associated with particular pieces of equipment are placed on a console or control panel, they shall be located on that console or panel to replicate the actual location of the equipment on the ship or structure as both are viewed by the operator. Therefore, equipment that is to the operator's left as he/she faces the control station shall appear on the left of the control panel or console, and equipment to the right shall appear on the right side of the console or panel. This "spatial relationship" between the real world and the controls and displays that are associated with the equipments and systems of that world is extremely important in the design of ships and maritime structures. 4.2.3 Humans develop behavioral patterns based on their cultural experiences. Designing a ship or structure that ignores or violate those culturally derived behavior patterns will inevitably lead to human error. |

||||

| Just How Big is a Million Lines of Code? | ||||

|

A million lines of code. It's a number bandied about more than ever as software sizes develop overactive pituitaries. Some cell phones use upwards of twenty million. Last year Ford announced that the F150 truck has 150 million. Everett Dirksen once may have said: "A billion here, a billion there, pretty soon you're talking real money." Well, a million lines of code here, a million there, pretty soon you're talking about a program that is as mind boggling and incomprehensible as our national debt. A million lines of code printed out would be 18,000 pages. That's a stack six feet tall (on typical 20 pound paper). Ironically, the listing weighs in at 180 pounds while the actual operating code is mass-free; it'll live in a fraction of a gram of silicon. Like DNA, code's human-readable description requires tremendously more mass than its actual instantiation. A million lines of code is probably on the order of 20 million instructions, or around half a billion bits. That's not far off of the 3 billions base pairs in human DNA. Unlike DNA, which has redundancies and so-called "junk" sequences, every single bit in the code must be perfect. A single error causes greater or lesser failure. Since a typical atom is around 0.3 nm in diameter, if one had as many atoms lined up as the number of instructions needed for a million lines of code, they would stretch 10 cm. That many Ebola viruses would stretch 15 meters. A million lines of code is as long as 14 copies of War And Peace, 25 of Ulysses, 63 copies of The Catcher in the Rye, or 66 copies of K&R's C Programming Language. A million lines of code is not ten times more than 100,000. It's well-known that schedules grow exponentially faster than the code. Barry Boehm estimates the exponent is around 1.35 for embedded software. So the schedule for developing a million lines of code is 22 times bigger than for 100,000 LOC. In the March, 1996 issue of IEEE Computer Watts Humphrey published crude rules of thumb for estimating software projects. Though hardly scientific, they do give a sense of scale. Using his estimates:

A million lines of code costs $20m to $40m. That's the cost of an F-18 jet, a thousand cars (in America), �ten million gallons of gas, seven times the inflation-adjusted cost of the ENIAC, and something like ten million times the cost of the flash chips it lives in. Think about that last analogy: Ten million times the cost of the flash chips. Accounting screams over each added penny in recurring costs, while chanting the dual mantras "software is free," and "hey, it's only a software change." |

||||

| This Week's Cool Product | ||||

Hex-Five Security's MultiZone product is a software layer that uses hardware to enforce high security when using untrusted code. Currently RISC-V versions are available.

It's a small (under 2 KB) bit of code that is formally verifiable. That's a big selling point when pursuing a Common Criteria security standard. As I understand it, the product enforces separation zones to keep bad actors out of others' sandboxes, which sounds like the Common Criteria's separation kernels. A datasheet is here. It's free for non-commercial use. Note: This section is about something I personally find cool, interesting or important and want to pass along to readers. It is not influenced by vendors. |

||||

| Jobs! | ||||

|

Let me know if you’re hiring embedded engineers. No recruiters please, and I reserve the right to edit ads to fit the format and intent of this newsletter. Please keep it to 100 words. There is no charge for a job ad.

|

||||

| Joke For The Week | ||||

These jokes are archived here. The primary purpose of the DATA statement is to give names to constants; instead of referring to pi as 3.141592653589793 at every appearance, the variable PI can be given that value with a DATA statement and used instead of the longer form of the constant. This also simplifies modifying the program, should the value of pi change. - FORTRAN manual for Xerox Computers |

||||

| About The Embedded Muse | ||||

|

The Embedded Muse is Jack Ganssle's newsletter. Send complaints, comments, and contributions to me at jack@ganssle.com. The Embedded Muse is supported by The Ganssle Group, whose mission is to help embedded folks get better products to market faster. We offer seminars at your site offering hard-hitting ideas - and action - you can take now to improve firmware quality and decrease development time. Contact us at info@ganssle.com for more information. |

Click here to unsubscribe from the Embedded Muse, or drop Jack an email.

|

||||

|

You may redistribute this newsletter for non-commercial purposes. For commercial use contact info@ganssle.com. To subscribe or unsubscribe go here or drop Jack an email. |

||||

| Contents | ||||

|

||||

| Editor's Notes | ||||

|

Over 400 companies and more than 7000 engineers have benefited from my Better Firmware Faster seminar held on-site, at their companies. Want to crank up your productivity and decrease shipped bugs? Spend a day with me learning how to debug your development processes. Attendees have blogged about the seminar, for example, here, here and here. Engineering changes at an accelerating pace. The boss wants more bug-free code, today. Tomorrow he'll want even more in the same time-frame. Are you on top of the best ways to deliver it? Some tell me they just don't have time to attend seminars. I'm reminded of this:

It is important to fight today's engineering battle. But the war will be lost if you don't find better ways to win. This is what my one-day Better Firmware Faster seminar is all about: giving your team the tools they need to operate at a measurably world-class level, producing code with far fewer bugs in less time. It's fast-paced, fun, and uniquely covers the issues faced by embedded developers. I'll present the Better Firmware Faster seminar in Melbourne and Perth, Australia February 20 and 26th. All are invited. More info here. The early registration discount ends today. As I noted in a recent blog, I'm cutting back significantly on travel, so this will be my last trip to Australia. It's a beautiful country with great people, but a long way from my homestead in Maryland. Jack's latest blog: A Lack of Forethought |

||||

| Quotes and Thoughts | ||||

|

I never give anyone hell. I only tell the truth. They think it's hell. Harry S. Truman |

||||

| Tools and Tips | ||||

|

Please submit clever ideas or thoughts about tools, techniques and resources you love or hate. Here are the tool reviews submitted in the past. |

||||

| Freebies and Discounts | ||||

|

This month's giveaway is a Cypress CY8KIT-044 PSoC 4 M-series Pioneer kit.

Enter via this link. Brian Cuthie reports that the schematic editor/simulation software Micro-Cap is now free. See this. |

||||

| On Requirements Documents | ||||

|

How long are your requirements documents? How complete are they? Getting hard data is notoriously difficult in the software world. Capers Jones probably has more than anyone. He stresses the large standard deviation, but makes it clear that one can gain some insight from it. I view the data as an impressionist painting, where the outlines might be fuzzy, but one can still make out the general shape of things. The following table is derived from data in Jones' The Economics of Software Quality. It shows how many pages of requirements are found for various-sized projects. The "Requirements Completeness" column illustrates all-to-pathetically how short those pages are of the delivered functionality.